Hydraulic Bumpers

Bumpers are provided in compliance to either CMAA no. 70, or AIST standards. The optimal choice depends on the impact speeds, impact masses, required impact forces, deceleration, and space restrictions.

Designed to have a constant force over the entire compression stroke, the kenetic energy is evenly disapated over the entire stroke. The force displacement curves can be adjusted to accomodate undamped applications. Operating temperatures –30 deg C to +80 deg C. Higher temperatures use special seals. With lower temperatures low viscosity oil is used.

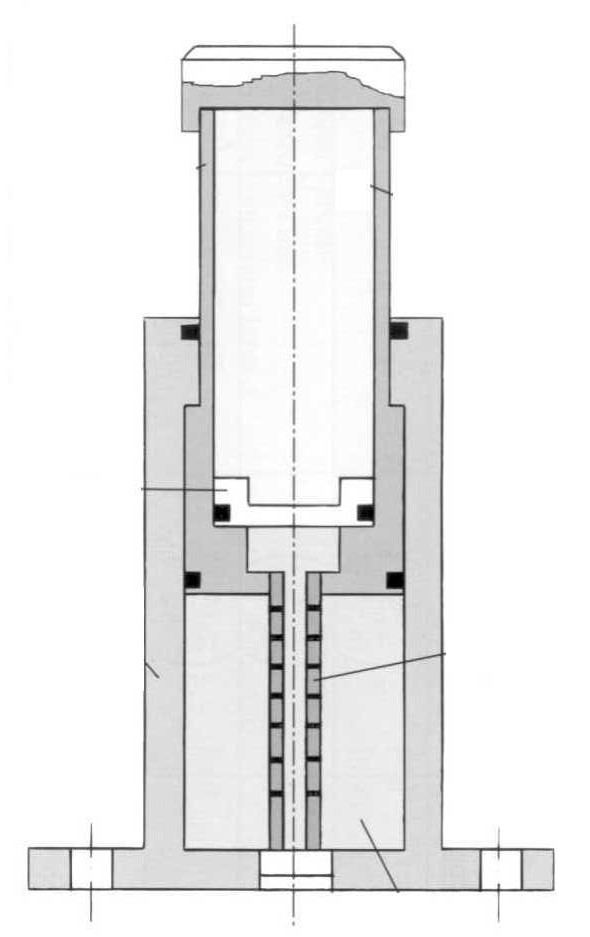

The damping function of the bumper a impact speed sensitive. With a high speed impact, the piston induces a high pressure within the hydraulic oil cylinder. Heat is generated and the oil is forced through the bore holes of the choke system. This compresses a gas spring which in turn generates the recoil force that extends the piston after impact. In a low speed impact the gas spring absorbs the kenetic energy.

KP

|  |

Energy capacity 4.5 kJ to 17000 kJ Piston surface IONIT-OX surface has better, longer lasting corrosion resistance than chrome plating. The harder surface means less wear, and longer equipment life than with chrome plating. Should an object be dropped onto the cylinder, the harder surface is less prone to damage. Sizing About 100 sizes available with 50mm - 1600mm stroke accomodates most impact conditions. This allows optimal energy handling for almost every application. Not only very heavy and fast impacts, very heavy and slow impacts, but also light and fast impacts can be handled efficiently. Mounting for front flange Bumpers Fully compressed our front flange mount bumpers have minimal approach distance between the face of the bumper head and the underside of the mounting flange. Metering Pin Our bumpers are fitted with a specific metering pin for the design impact. Every application is optimized. |