Cellular Plastic Bumpers

Bumpers are provided in compliance to either CMAA no. 70, or AIST standards. The optimal choice depends on the impact speeds, impact masses, required impact forces, deceleration, and space restrictions. Bumpers compressed up to 70% of the bumper length, result in little lateral expansion, stresses and so minimize material fatigue. Large deflections provide lower deceleration rates and protect equipment high impact forces. Cellular plastic bumpers have increasing force with increasing compression. This will result in fewer oscillations than constant force-compression bumpers when used in undamped applications. Resistant against ozone, oil, grease. Polyurethane is not stable with acids and bases. Operating temperatures –40 deg C to +80 deg C

16940

- 100 - 315mm diameter

- Energy capacity 1.2 kJ to 34 kJ

- black foamed polyurethane

- bumpers 100mm dia. feature alumimum base plate

- bumpers 125mm dia. and over have reinforced fiberglass mounting base for high strength, corrosion resistance and light weight

- The base plate is designed as a hold down ring, interlocked with the bumper

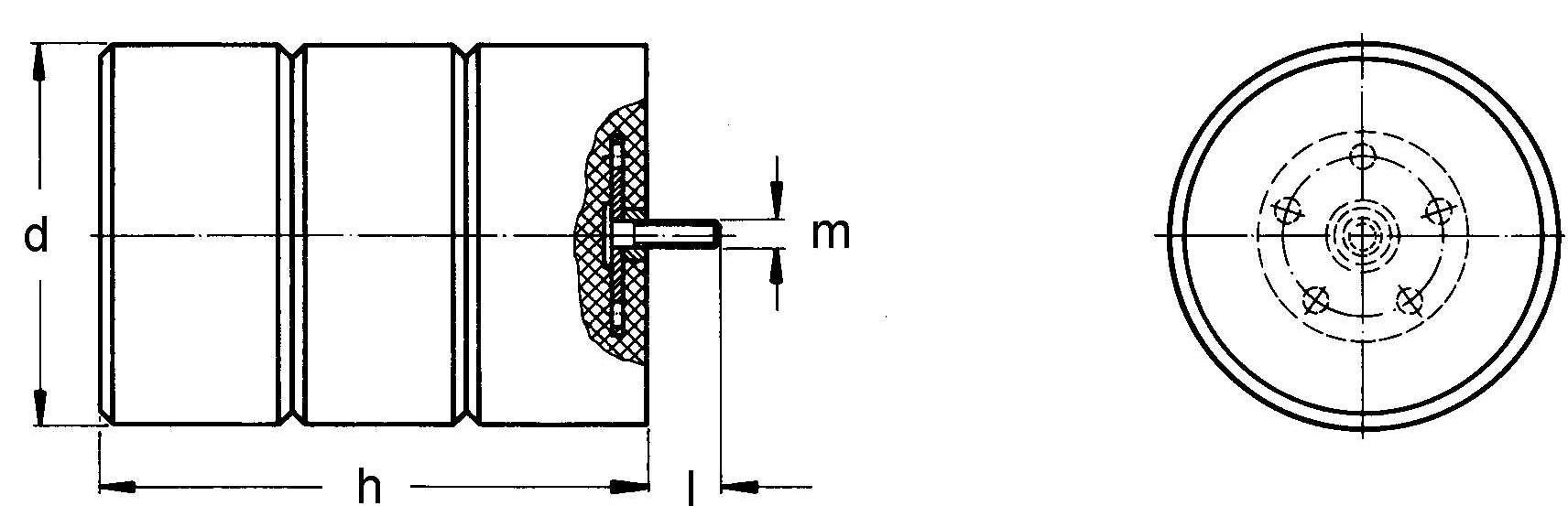

16941

- 80 - 600mm diameter

- Energy capacty 0.8 kJ to 950 kJ

- white (or beige) foamed polyurethane

- bumpers up to 200mm dia. feature aluminum base plate

- bumpers 250mm dia. and over have steel base plate

- for opposing bumpers we recommend models with height = diameter

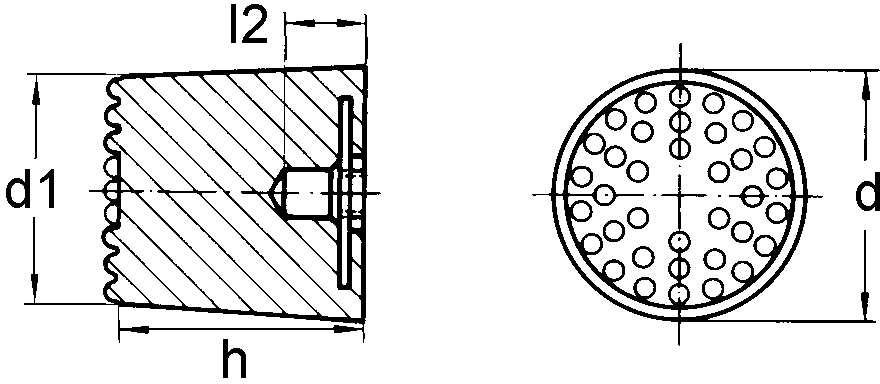

16942

- 80–400mm diameter

- Energy capacity 0.8 kJ to 282 kJ

- white (or beige) foamed polyurethane

- threaded stud mount

- for opposing bumpers we recommend models with height = diameter

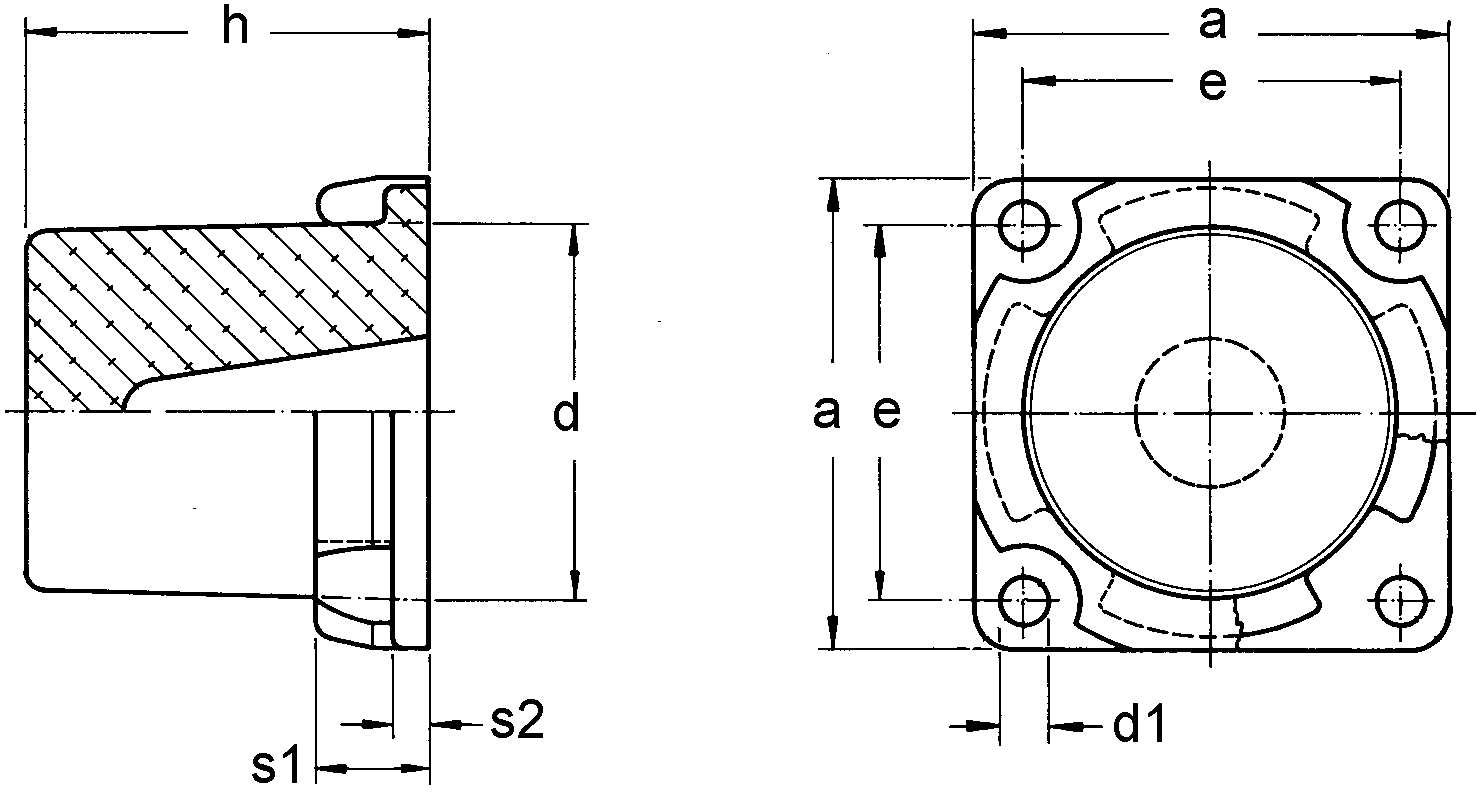

16944

- 70 - 210mm diameter

- Energy capacity 0.5 kJ to 8 kJ

- black foamed polyurethane

- removable threaded stud mount

Rubber Bumpers

Bumpers are provided in compliance to either CMAA no. 70, or AIST standards. The optimal choice depends on the impact speeds, impact masses, required impact forces, deceleration, and space. Excellent wear resistance. Special rubber 75 deg shore A. The mechanical characteristics like elastic strength, compression recovery, tear resistance are determined by rubber additives. Bumpers can compress up to 50% of the bumper length. The lateral deflection can be up to 1.4x the original diameter. Rubber is less suseptible to hydrolysis than foamed polyurethane.

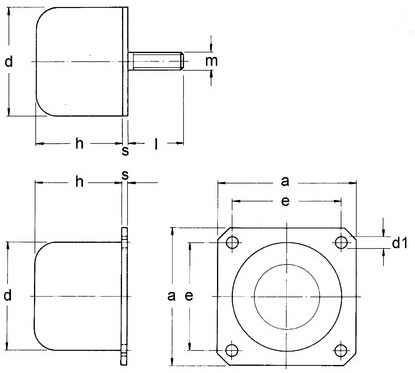

16951, 16952, 16953

- 40 - 315mm diameter

- Energy capacty 0.05 to 24 kJ

- 16951 has standard thickness steel base plate

- 16952 has heavy duty steel baseplate

- 16953 has threaded stud mount